Chimney Inspections - Why are they needed and what type do I need?

According to the National Fire Protection Association, it is recommended that a chimney be inspected once a year to ensure the system is safe. There are many issues that can begin to transpire with a chimney in a short period of time depending on the type of climate that you live in and the amount of use your fireplace endures. It is very common for birds to build nests inside the flue or smoke chamber, the interior or exterior of a fireplace can begin to deteriorate or creosote/soot may begin to build up inside the system making it unsafe to burn. These are just a few reasons why you should have your system checked regularly by an experienced chimney sweep. Our company provides a complete Level 1 Chimney Inspection. We inspect 20 aspects of your fireplace to make sure that your system is in good operating order and it is safe to burn.

What are the different types of Chimney Inspections:

Level 1 Chimney Inspection:

A level 1 chimney inspection is the most common type of chimney inspection. With a level 1 inspection, our chimney technician will visually examine the interior and exterior portions of your chimney. The visual inspection is performed with a flashlight examining all areas of your chimney and flue that can be viewed without the use of any special tools.

During the inspection, the chimney technician will make sure that the basic structure of the chimney is in tact and there are no visible signs of damage. In this inspection, your technician will also verify that there are no obstructions or combustible materials in your chimney. In addition, your technician will also let you know if you have an unsafe amount of creosote or soot in your system that could cause your fireplace to smoke or potentially catch on fire. Although ash is not a catalyst in aiding fires, there are other issues that can arise from having high amounts of ash in your fire box or underneath your grate such as smoking or drafting issues due to air circulation problems.

Level 2 Chimney Inspection:

A level 2 chimney inspection is conducted by running a specialized inspection camera through the interior of the fireplace to inspect for concealed damage to the flue lining, as well as the inspection of the exterior of the chimney.

Level 3 Chimney Inspection:

A Level 3 Chimney Inspection is usually required when the construction of the chimney has potentially unseen defects. The Level 3 inspection could include opening or removing an interior wall to access hidden parts of the chimney. This level of inspection normally occurs when a more serious problem has been identified and a method of repair needs to be determined.

What are the different types of Chimney Inspections:

Level 1 Chimney Inspection:

A level 1 chimney inspection is the most common type of chimney inspection. With a level 1 inspection, our chimney technician will visually examine the interior and exterior portions of your chimney. The visual inspection is performed with a flashlight examining all areas of your chimney and flue that can be viewed without the use of any special tools.

During the inspection, the chimney technician will make sure that the basic structure of the chimney is in tact and there are no visible signs of damage. In this inspection, your technician will also verify that there are no obstructions or combustible materials in your chimney. In addition, your technician will also let you know if you have an unsafe amount of creosote or soot in your system that could cause your fireplace to smoke or potentially catch on fire. Although ash is not a catalyst in aiding fires, there are other issues that can arise from having high amounts of ash in your fire box or underneath your grate such as smoking or drafting issues due to air circulation problems.

Level 2 Chimney Inspection:

A level 2 chimney inspection is conducted by running a specialized inspection camera through the interior of the fireplace to inspect for concealed damage to the flue lining, as well as the inspection of the exterior of the chimney.

Level 3 Chimney Inspection:

A Level 3 Chimney Inspection is usually required when the construction of the chimney has potentially unseen defects. The Level 3 inspection could include opening or removing an interior wall to access hidden parts of the chimney. This level of inspection normally occurs when a more serious problem has been identified and a method of repair needs to be determined.

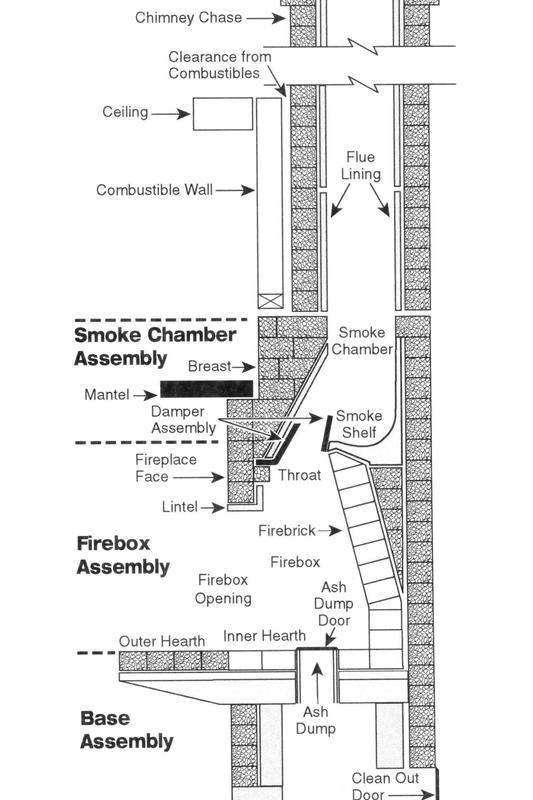

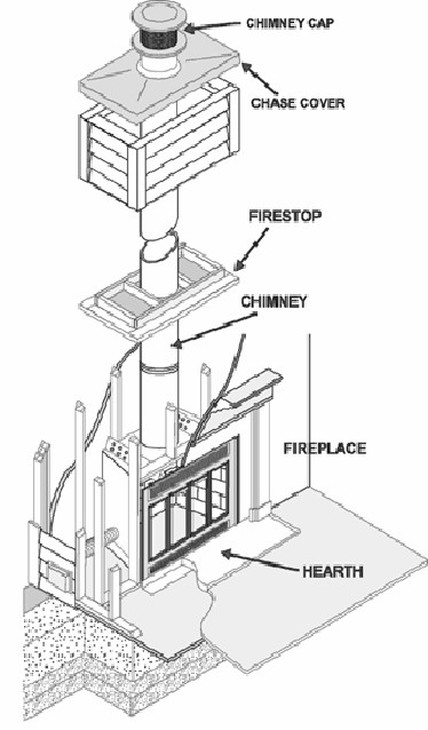

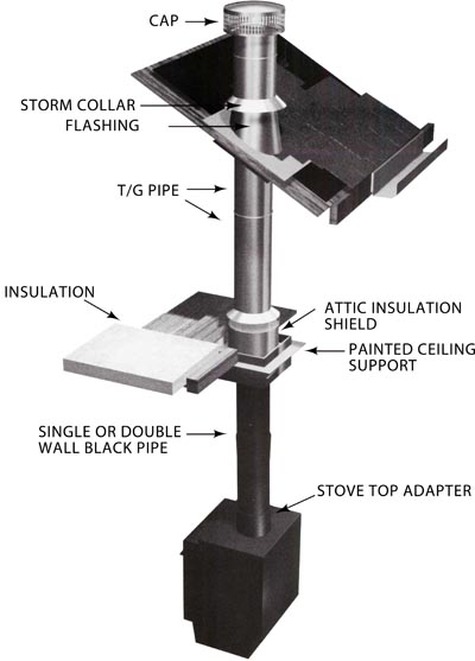

Becoming Familiar With The Areas Of Your Fireplace

|

General Masonry Fireplace DiagramGeneral Factory Built Fireplace Diagram

General Stove Pipe Diagram |